Teie partner suure mõjuga tööstusharudele mõeldud staatilise protsessitehnika valmistamisel

Pakume terviklahendusi projektidele erinevates suure mõjuga tööstusharudes, alates disainist ja projekteerimisest kuni dokumentatsiooni vormistamise, tarne ning paigalduseni. Teeme teiega tihedat koostööd ja võtame vastutuse saavutamaks tulemus, mida teie tööstus ja projekt vajavad. Estanci tegevus põhineb meie neljal põhiväärtusel:

Inimesed

Panustame pühendunud juhtimisele, töötajate ja klientide rahulolule, õnnelikele peresuhetele ja tugevale partnerlusele.

Kirg

Me hoolime. Oleme pühendunud. Ja tõeliselt naudime seda, mida teeme.

Eesmärk

Meie jaoks on oluline, et kõik, mida me teeme, oleks eesmärgipärane.

Protsess

Usume protsessipõhistesse tegevustesse, mis toetavad eesmärkide saavutamist.

Tööstused, mida teenindame

Ülekaalukalt meie suurim projektisektor

Oleme projekteerinud ja tootnud seadmeid suurematele tselluloosi ja paberitööstuse tehastele üle kogu maailma, koostöös oma partneritega tarninud igaühte neist mitukümmend seadet.

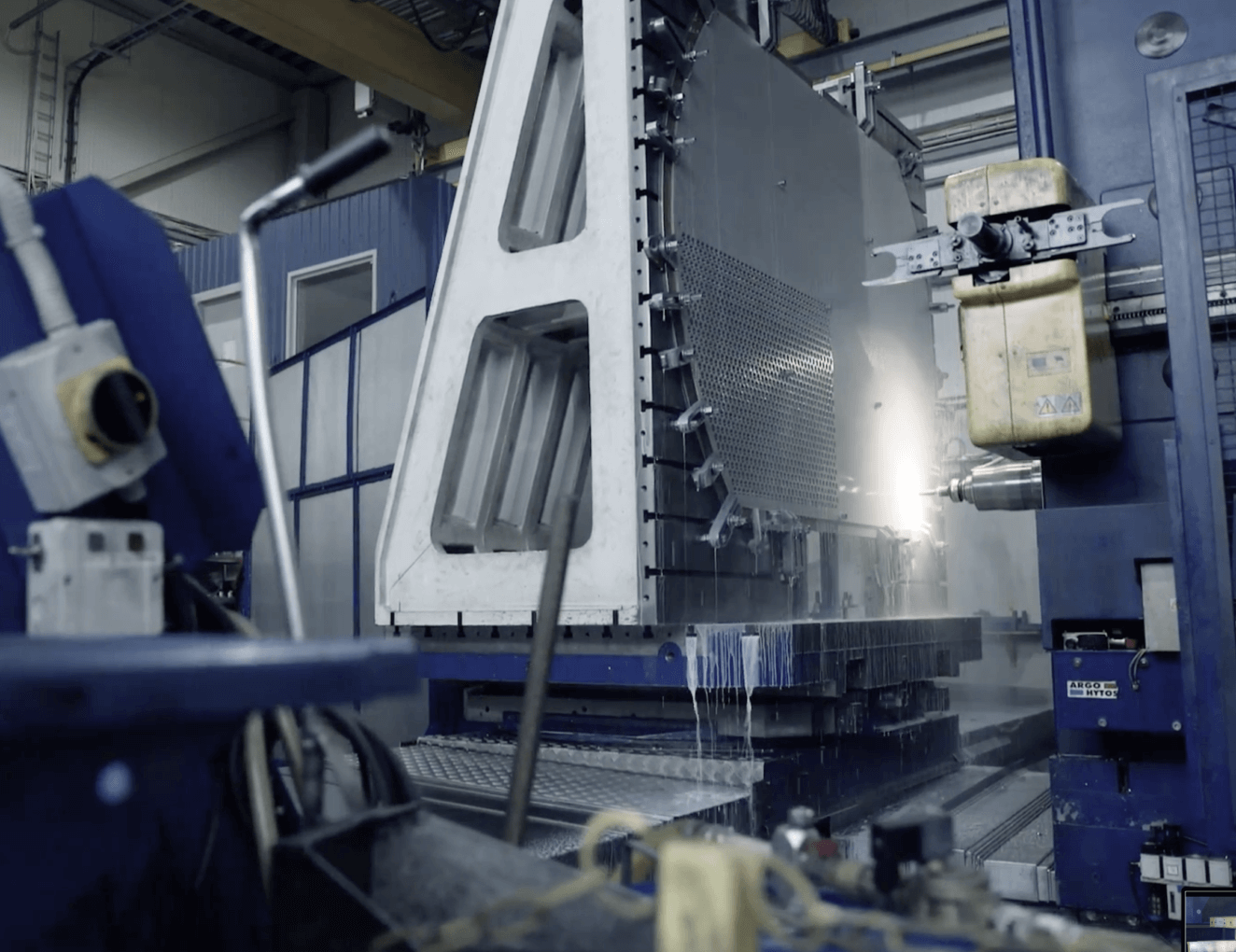

Tipptasemel tootmishoone

Esimesest kontaktist tarne ja paigalduseni

läbi mõeldud tegevust

pühendunud töötajat

erinevat teenindatavat sektorit

aastat kogemust

Meeskonnast

Kes me oleme

Me oleme kirglik ja koostöövalmis meeskond, kes soovib iga päev üha paremini hakkama saada.

Mida me väärtustame

Tahame olla kestliku ja eduka maailma loomise lahutamatu osa.

Ühine meiega

Pakume võimalust töötada nüüdisaegses ja agiilses tootmisettevõttes, kus väärtustatakse igaühe ambitsioone.

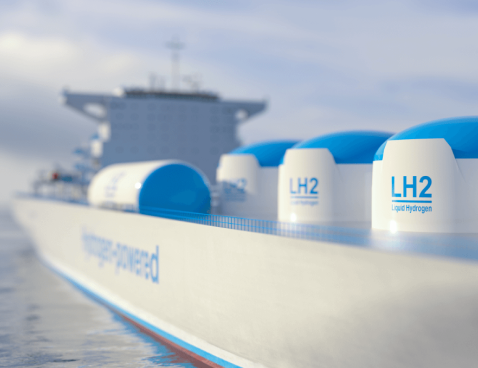

Jätkusuutlikud protsessid on meie DNAs

Keskendume oma jõupingutustes valdkondadele, kus saame anda suurima positiivse mõju. Arvestame, et meie tooted aitavad kaasa tööstuse ja maailma suurimate jätkusuutlikkuse probleemide leevendamisele.