Implementing “6S Lean” methodology in our production plant

Since of February 2019, Estanc has held workshops to implement Lean 6S quality management Methodology in our production plant in an effort to improve our processes.

Since of February 2019, Estanc has held workshops to implement Lean 6S quality management Methodology in our production plant in an effort to improve our processes.

In these days, quality is not only one issue in manufacturing sector but to achieve a high performance, high utilization of raw material, full utilization of machines and tools, save production time, providing better work environment to the workers and safety of workers etc.

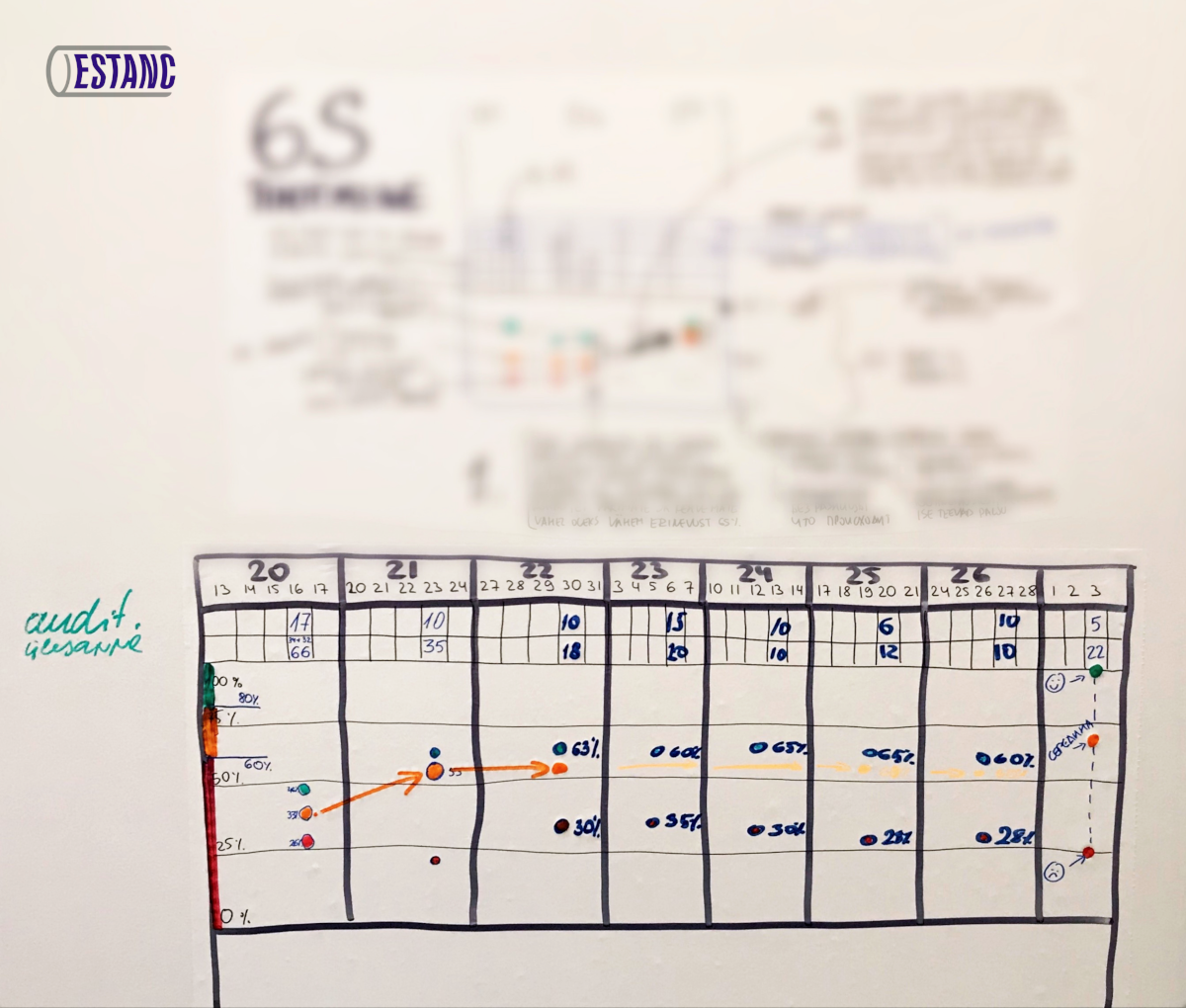

The 6s workshops were held once a week and targeted to our production personnel with the aim to promote and sustain a high level of productivity and safety in our production throughout a workspace. These sessions were conducted by Lean Enterprise Estonia, who specialize in dealing with promotion, training and consultancy of lean thinking principles.

The pillars of 6S

The 6s Methodology includes familiar steps found in 5s (Sort, Set in Order, Shine, Standardize, Sustain), but adds the concept of Safety. One of the aims of 6S is to establish a sustainable culture of safety – zero accidents and zero near misses.

A powerful tool in the workplace

The 6s principles provide a framework to harmonize Estanc’s occupation-based processes and create a system for better performance. It helps to decrease waste while optimizing productivity through maintaining an orderly workplace, using visual cues to attain more consistent operational results. Through the system we achieve more efficiecy in production and higher quality products.

Since 6s is a systematic form of visual management, one of the most important developments Estanc made, would be building a digital planning module from previous Excel spreadsheet into our ERP system. We now plan, schedule, visualize and give feedback to day-to-day production operations via ERP systems. Visualizing the work flow gives a better overview of current project status in all management levels and provides the opportunity to plan daily tasks accordingly.

Successful implementation of the 6s principles will require high-level commitment and constant process transformations, but we believe that through the system of striving for improved productivity favors us to be more successful and sustainable in the long run.