Reference projects 2019

In 2019 Estanc received 88 orders, containing 200 units of equipment. Over previous two years the number of projects have been decreased, 73 projects in 2018, compared to 116 projects in 2017 and 156 projects in 2016. In the past two year period we have targeted bigger, more complex and time-consuming projects which require more working hours and longer delivery. Besides that, according to our business strategy, we have made efforts to enter greentech markets which offer solutions to environmental issues. Currently we are working with few prototyping projects of which we’ll be sharing some insight soon. Due to our long experience and expertise we have gained during almost three decades in the field, we’re able to offer wide product portfolio and we are open to partnerships in new market segments.

Here we are featuring highlight projects of 2019 that for one reason or another were firsts for us.

327 bar Sweet Water Condenser, high pressure heat exchangers for ARAUCO MAPA project in Chile

This project was a landmark in terms of high pressure and technological challenges due to the high pressure. This feedwater preheater with the testing pressure of 327 bar sets a record for the highest test pressure on equipment manufactured by Estanc so far. Thick materials, the design of the heat exchanger and testing with such high pressure was a first of its kind for us, giving us the ability to further develop our competence in that product category.

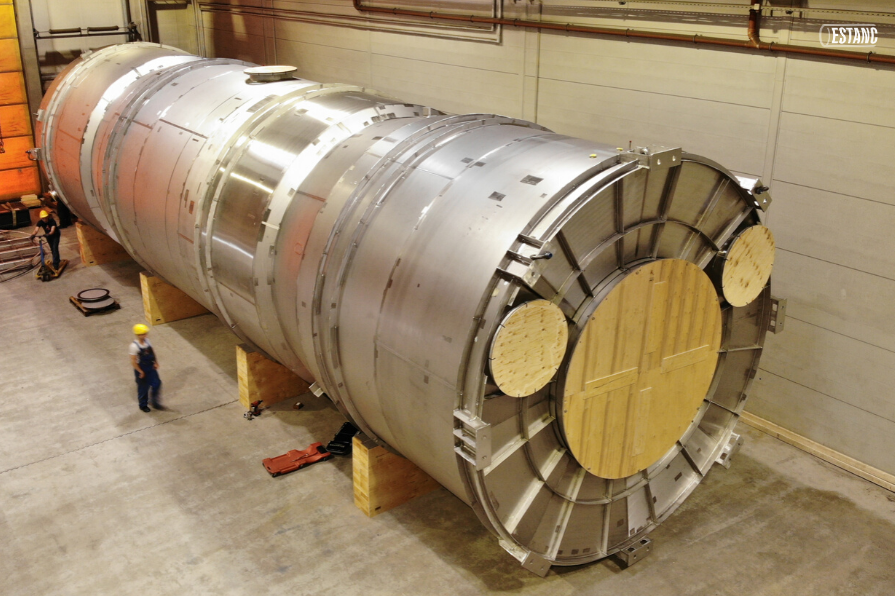

857m3 feedwater tank- the biggest unit manufactured and transported in one piece in Estanc’s history

The production of this 194-ton feedwater tank and deaerator with the length of 38 500mm and diameter of 5,500 mm was a new milestone for Estanc. A product with such large dimensions has not been manufactured in Estanc before. All that posed challenges for both the production area and human resource planning. Internal logistics operations had to be carefully considered, because at some stage of the project the weight of the feedwater tank was so heavy that it was not possible to move it in the plant with its own cranes and alternative product displacement options had to be implemented special purpose trailers.

The production of this 194-ton feedwater tank and deaerator with the length of 38 500mm and diameter of 5,500 mm was a new milestone for Estanc. A product with such large dimensions has not been manufactured in Estanc before. All that posed challenges for both the production area and human resource planning. Internal logistics operations had to be carefully considered, because at some stage of the project the weight of the feedwater tank was so heavy that it was not possible to move it in the plant with its own cranes and alternative product displacement options had to be implemented special purpose trailers.

See the transportation video HERE

Flue gas condenser featuring 12,000 tubes

On March 2019 we shipped this 198-ton flue gas condenser, which is the heaviest heat exchanger Estanc has ever manufactured in one piece.

On March 2019 we shipped this 198-ton flue gas condenser, which is the heaviest heat exchanger Estanc has ever manufactured in one piece.

5150mm diameter, featuring 12,000 tubes with total length of 200+km which for example is a 2,5 hour driving distance from Tallinn to Tartu. The tubes were welded using orbital welding and overall was time consuming due to large dimensions of the equipment and the amount of tubes featured.

The condenser’s final destination was a Power plant located in Oulu, Finland, where it helps to increase the efficiency of the plant.

See the project video HERE

11 unit marine scrubber project for world’s largest container ships

Estanc has manufactured a total of 90 scrubbers, being one of the leading manufacturers and suppliers of marine exhaust scrubbers in the market in terms of experience and compliance.

Estanc has manufactured a total of 90 scrubbers, being one of the leading manufacturers and suppliers of marine exhaust scrubbers in the market in terms of experience and compliance.

Although we spoke about this project in 2018, the last scrubber was transported at the end of 2019. This was a monumental project for Estanc, being the biggest project ever sold in working hours and turnover. With this project we had the opportunity to contribute to sustainability in shipping and green technologies, developing the best solution for the future. These Ø5,620mm and 20m long scrubbers were shipped to Soth-Korea and installed to world’s largest container ships.

We’re happy to partner up with Yara Marine Technologies for this marine scrubber order which help contribute to SDG13 Climate Action by lowering CO2 emissions.

See the video of the production of the world’s biggest marine scrubber HERE

Subscribe to our Linkedin page to stay connected with our latest activities